|

We

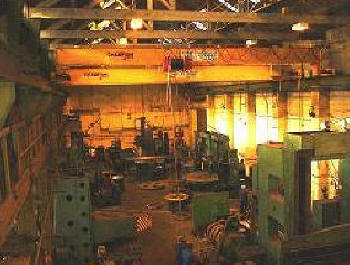

have extensive machining facilities at our Works in Hyde, including

turning, planing & horizontal boring.

Please see below for our full machining capacity list. In the machine shop we have the capacity to lift and machine parts to a maximum individual component weight of 30 Tons, with modern overhead travelling cranes. Our machine shop has a dedicated fitting area, with all the facilities needed for building & testing forging machines. Because all machining is completed ‘in house’ it allows us to turn your project round faster, without compromising quality. In the event of components exceeding 30 Tons we can handle them in our storage bay to a maximum of 45Tons. |

|

|

PLANT AND CAPACITY LIST:

VERTICAL BORING: ENTWISTLE AND

GASS: 132" diax66" HEIGHT UNDER RAIL HORIZONTAL BORING: KEARNS: 14' CROSS 13' LONG 8'6"

HEIGHT PLANING: RICHARDS: 26' LENGTH x 10' WIDTH

x 9' HEIGHT DRILLING: RADIAL ARM: 6' SWING MAX (2 MACHINES) TURNING: COLCHESTER MASCOT 2000: 7' MAX

BETWEEN CENTERS TOOL ROOM: FACILITIES INCLUDE: JIG BORING / SURFACE GRINDING / CYLINDRICAL GRINDING / MILLING / SAWING & SLOTTING (MAX 16" STROKE) ADDITIONAL FACILITIES: Other facilities we have available on site include fabrication (coded welders) to 25 tons, profiling, shot blasting, painting and stress relieving. |

|